EV Battery Manufacturing

EV Battery manufacturing sites are dependent on heating and cooling for operational efficiency to maintain dry rooms and to manage process and equipment temperatures. Uptime of these processes is critical to meeting the demands of this growing market.

Nalco Water can provide the expertise for a smooth startup and continuing operations today and to position our customers for success in the future.

Featured EV Battery Solutions

Heating and Cooling

From your main utilities to testing cooling towers, 3D TRASAR™ Technology provides visibility and control in EV Battery manufacturing verifying optimized cooling to maintain production uptime while improving water sustainability.

Site Design and Start-up

As the need for more battery capacity grows, Nalco Water is your partner to help design your water system and get the site up and running smoothly. With over 75 transportation manufacturing site start-ups, our expertise is unmatched.

Related EV Battery Manufacturing Solutions

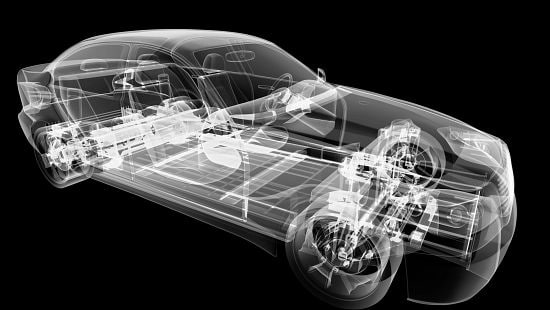

The electric vehicle (EV) battery market is surging as traditional automakers announce plans to go all-electric and new EV players continue to emerge.

Building new battery plants, though, is only half the battle. Battery manufacturing requires significant heating and cooling resources. Reliable utilities, specifically cooling and boiler systems, are essential for any EV battery producer to hit their productivity and profitability targets.

Design is the best stage in which to build in the features that support reliable, sustainable and easy-to-start-up utility systems. An ounce of prevention is worth a pound of cure: Building with water efficiency in mind helps EV battery producers be good neighbors in the communities where they operate, and good stewards of their local watersheds. Doing this up front also helps prevent lengthy construction delays and costly retrofitting.

The Automotive experts at Nalco Water compiled the top 10 mistakes we see at new plant start-ups worldwide, including issues unique to EV battery plants. Our team offers design and planning recommendations as preventive measures, plus mitigation tips when necessary.

Complete the form to receive our whitepaper and learn more.